Cabinet Based Trolley Pole

The CBTP ranges is the very peak in CCTV mounting poles. With various options of built in or transferable electric or manual winches, the ranges enable cost-effective and more importantly safe camera maintenance at ground level. These columns has been designed within the Highways Agency specification and with their excellent reliability record, have become the number one choice in urban traffic monitoring schemes. The CBTP range has the added bonus of a spacious cabinet base at the bottom for more complex electrical and communications use.

Design Features

- The ideal column for urban and traffic CCTV schemes.

- Eliminates use of mechanical lifts for servicing purposes.

- Integral lockable cabinet base for housing telemetry, fibre optics, spurs etc.

- Safe camera maintenance at ground level, where camera head can rotate through 180 degrees vertically and horizontally for servicing purposes.

- Various built in and transferable winch options.

- In-built carriage failsafe braking mechanism.

- Excellent stability characteristics ensures minimal camera movement.

- Recommended for installation in high profile and public places.

- Options include double door and split cabinets.

- Suitable for all public access areas.

- Camera carriage unit has a self clamping mechanism to minimise deflection when in its working position.

- Totally concealed cable management facility.

- High security door option for high risk areas

- Hot dipped galvanised finish for maximum weather protection and low maintenance requirements.

- Custom and bespoke versions tailored to the customer's requirements.

General Specification

- Standard pan and tilt fixing of 101.6 PCD.

- Special dome mounting brackets available.

- Built in cable entry and exit point.

- Flange mounted TC type root.

- Pocket type roots available for restricted foundation locations.

- Heavy duty version loadings up to 25 kg.

- A large variety of standard heights from 4 to 15m*

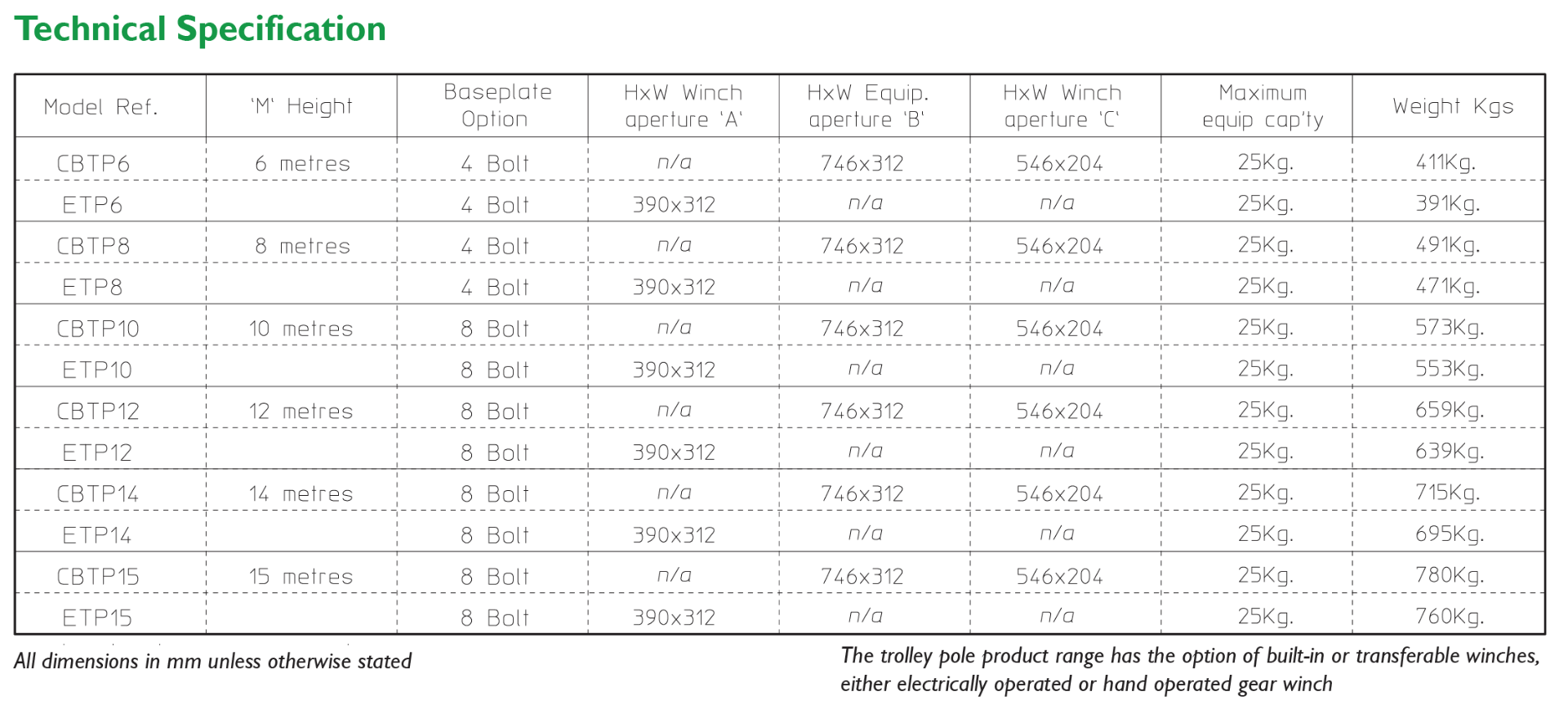

*See Technical Sheet for further information, please note the heights specified are nominal and may vary.

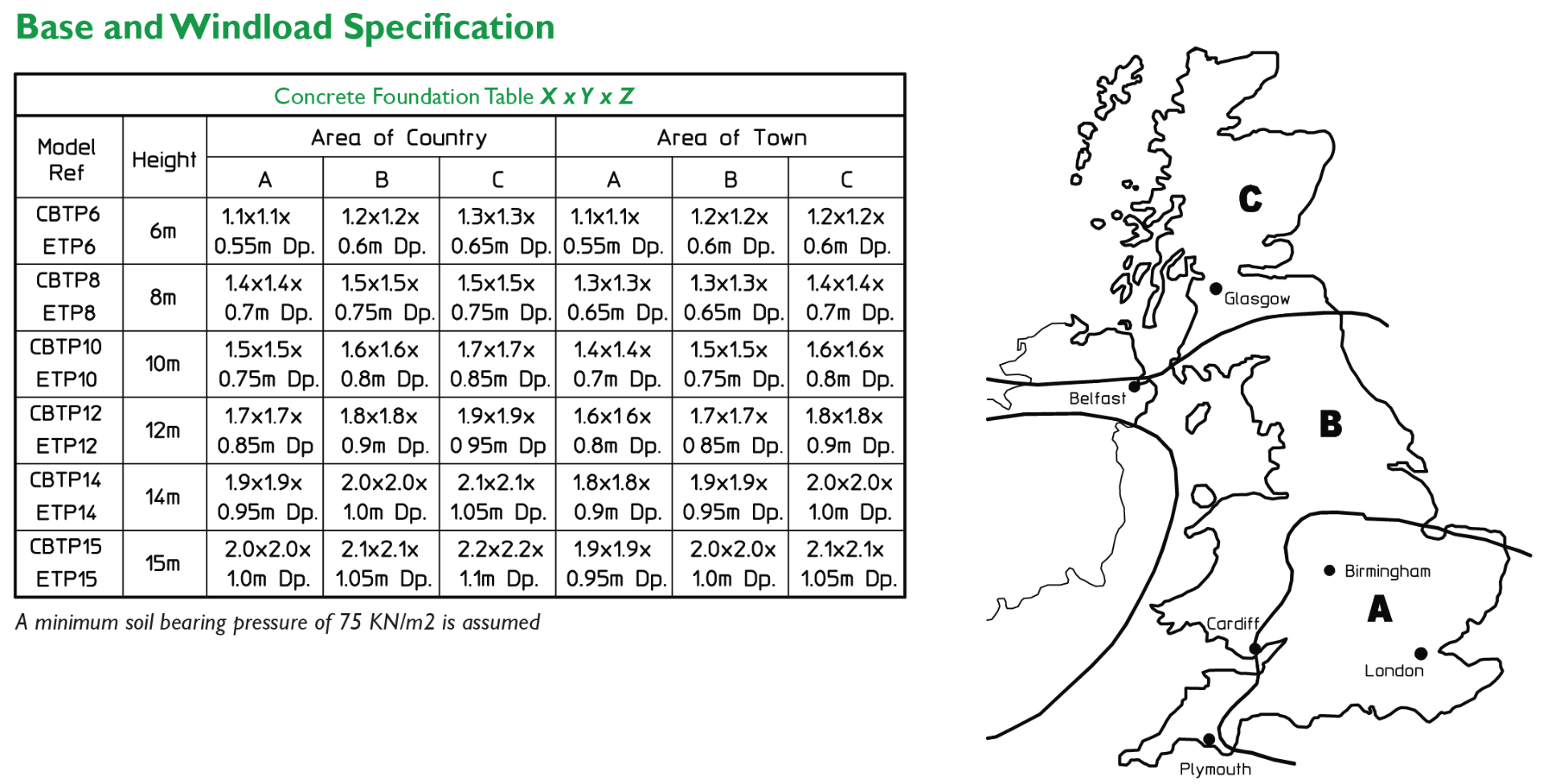

1. From the map, select location of installation

2. Excavate as per recommended area and depth

3. Assemble root base as shown in fig. 1

4. Insert root base into the hole ensuring that it is

level and that the four studs protrude 60-70mm

above the concrete foundation

5. Fit the cable duct if routing via the interior of the

column. A plastic pipe of approximately 100mm

outside diameter is recommended for this. Ensure

this protrudes through the template by 50mm minimum.

6. Pour concrete ensuring that it is a mix of C35

to table 6 BS 8110 and then tamp down well

7. Fit the setting template over the four protruding

studs, double-checking that they are level and that

clear access can be gained to the cable duct if it

is being used

8. Leave the concrete to cure for a minumum of 72

hours prior to attempting to erect the column

9. When fitting the column, ensure that the concrete

base is in complete contact with the underside of

the column and grout accordingly. Torque the nuts to

230-270 Nm (175-200 fl. lb.)

10. When the column has been fitted, protect the studs

with a suitable protective coating. Denzo tape or

similar is recommend for this